Products

DWG-3000 Full Auto Wire Mesh Welding Machine

DWG-3000 full auto wire mesh welding machine

Introduction of DWG-3000 full auto mesh welding machine:

With the high-speed development of construction industry and the application of new technology, steel bar welded mesh, as a new type, high efficiency, energy saving, reinforced concrete structure building material, has been architecture widely recognized. It has increased the strength of structure, steel saving, labour saving and convenient transportation and construction, high dimensional accuracy, easy to specialization, large-scale production, high comprehensive economic benefits etc. Many countries have made the corresponding regulations and standardsto expand promotion of welded steel fabric in various fields, now the welded steel fabric has been widely and mainly used in construction, industrial and civil construction concrete; transportation: high-speed railways, highways, tunnels, bridges, airports; water conservancy, port, electricity, and warehouse facilities; environmental protection facilities, entertainment; coal industry, animal husbandry, forestry, husbandry, etc.

DWG - 3000 mesh welding machine (as shown in figure 1) absorbs foreign advanced experience, on the basis of advanced technology and combined with domestic actual production requirement. The machine can weld hot rolled ribbed steel bar, cold rolled ribbed steel bar, round ribbed steel bar, light round for high quality cold drawn steel cross welding, large output, high precision, easy modification, operation, low failure rate, energy-saving, low consumption and high quality. The features is as following:

It’s pneumatic welding, servo drive and PLC controled, the mesh width, mesh opening can be stepless adjusted accurately.

Set welding parameter on the touch screen to be easier for adjust.

There are buttons and switches on the operatiob panel, you can choose the welding method and control the movement

Welding wire diameter: 1.7-3.5mm

Mesh width: 3000mm

Mesh size: 50-200mm, can be adjusted

The electrode can be move, welding speed is 40 strokes/min

To promise good welding quality, the welding current, welding time, welding pressure, etc can be adjusted according to the material.

Key transmision part, working part, electric part, penumatic part are apply international brand, can support long service life and high accuracy.

Welding transformer, electrode, secondary wire and main circuit of SCR control system are water cooled.

According to the power supply, you can choose one-time welding or 3-time welding.

There is less spark and low noise in the welding proceed.

Easy operatiob and maintain.

Match with basement, easy for installation

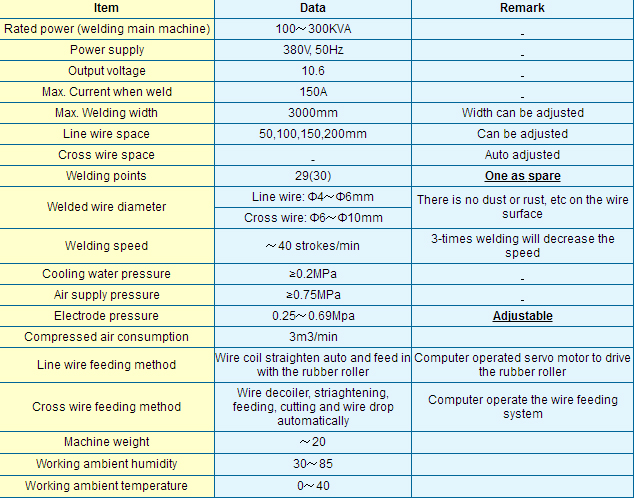

Main parameter:

DWG-3000 mesh welding machine sizes:

Installation space: about 30m*7m

Line wire pay-offs (L*W*H): ~4000×5000×1100mm

Line wire straightening sturcture (L*W*H): ~600×900×1200mm

Welding machine (L*W*H): ~5200×1300×1800mm

Rubber roller mesh pulling system (L*W*H): ~4700×1800×2000mm

Mesh length sensor part (L*W*H): ~3300×500×1500mm

Mesh clampsing cylinder control frame (L*W*H): ~3300×600×1800mm

Mesh recoiling part (L*W*H): ~52000×1300×800mm

Wire feeding assist part (includes on-off control part)

Cross wire lift frame part

Control cabinet (L*W*H): ~ 1200×600×2200mm

Control panel (L*W*H): ~500×420×1080mm

Others: like air pipe, cross wire feeding frame, spare parts, etc

Material requirement:

Strength standard value: 450-650 MPa, elongaration: δ10= 6-12%

There is no dust or insulation material, etc which will inflent the welding quality

Material length tolerance should match with welding technology;

Welding material should match with related welding standard

Typical application of welded wire mesh